The PMCD represents the final stage in the production process. It is superseded only by the creation of the glass master disc. The glass master, made directly from the PMCD supplied to the duplication house, then becomes the "parent" disc from which every disc in a production run is duplicated.

PMCD, or "Pre-Master CD" is

a definition originally developed by Sony/Sonic Solutions to describe a specification for optical media (CD's) to be used for glass-master duplication.

The term has come into wider use, now no longer referring only to master discs burned on a Sonic Solutions workstation, but to compact discs falling below specified error rates in several areas.

|

PMCD's acceptable for glass-master and error-free short-run duplication must be E:32 error-free, with a BLER rate of 220 or lower. (See below for further explanation of these error types.) Glass-master duplication plants generally also require a frame-accurate PQ log, showing track titles with start/end times in minutes, seconds, and frames (1/30th of a second).

All D. M. Gremlin Studios masters are burned on a Plextor PremiumWriter drive, and tested using the PlexTools Professional Q-Checks. The master discs are burned at slow speed on archival gold CD's, for the highest burn accuracy, lowest error rates and longest disc lifespan. The Q-Check error tests verify that each disc is within the required PMCD standards. |

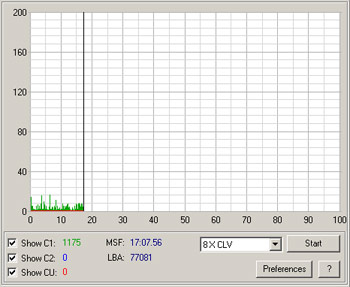

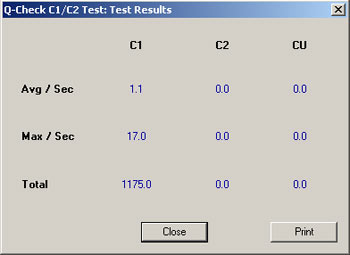

Above, and right: Graphical and numerical Q-Check results for a recent Stark Raven master.

PMCD spec allows for a BLER rate (C1 errors/sec) up to 220. The BLER rate for this disc is 1.1, with zero C2 errors. No CU's (critical errors) are present.

|

|

|

|

Compact discs inherently contain certain types of errors due to physical limitations of the media (the pits in the disc being smaller than the wavelengths of light used to read them). The number and type of errors present in a just-burned CD vary depending upon the software/hardware configuration and the manufacturer and quality of the disc used. The quality of media used also affects the degradation over time of the disc, and therefore the rate of introduction of new errors, to the point where a disc may become uplayable after a certain period of time.

Compact disc playback devices contain several levels of error-correction, allowing for the disc's information, errors included, to be translated into error-free audio playback. However, CD's can also contain errors severe enough that they cannot be corrected. These "critical errors" can be present in the disc when burned, or can occur over time due to degradation of poor-quality media or improper storage/handling (scratches, dust, etc). Critical errors in a disc often result in audible errors upon playback: clicks, pops, dropouts, or digital distortion. However a critical error may also be inaudible during playback, yet still result in audible glitch in a duplication run made from that disc.

To ensure that production runs of a CD are error-free, most glass-master duplication plants will error-check a master disc, and reject it if it is not within PMCD specifications. This measure assures an error-free duplication run, but it can set back the production schedule if a master disc is not up to par and a new master must be provided. Short-run operations generally will NOT perform any error-checking, therefore allowing for the possibility that undetected errors in the master CD can cause a duplication run containing audible flaws.

The error types pertinent to PMCD specifications are C1 and C2 errors, critical errors (CU's), and BLER rate. C1 errors are normal and expected in any disc. These are corrected within the first level of error correction during playback. Individual C1 errors cause no problem in either playback or duplication. C2 errors are errors that cannot be corrected by the first level of error correction, and are passed along to the second level. There are 3 levels of C2 errors, with the third level, or E32 error, considered uncorrectable and classified as a critical error (CU). A single critical error will cause a disc to be rejected in the glass master process. While only an E32 will cause a disc to be rejected outright, a quality hardware/software/media combination should have no trouble producing a disc free of all C2 errors..

The final error classification of concern in a PMCD is the BLER rate. BLER, or Block Error Rate, concerns the average rate of C1 errors per second. While not an issue individually, frequent patterns or long strings of C1 errors within the same data block can also render a disc unsuitable for duplication. PMCD standard calls for a BLER rate of under 220 per second, though an archival-quality disc burned with the an appropriate hardware/software configuration will have a BLER rate a fraction of the acceptable margin. |